The former Rog factory is an important monument of industrialisation in Slovenia.

Text by Tatjana Adamič

Historical starting points

The beginnings of leather tanning activity on the factory site in the Šempeter suburb date back to the 1870s, when the tanner Ivan Janež first built a ground-floor tannery on the site and later erected a single-storey factory building, the largest in Ljubljana at the time. The span of the vaulted arches was approximately 8.5 m, and the length of the factory hall was approximately 120 m.

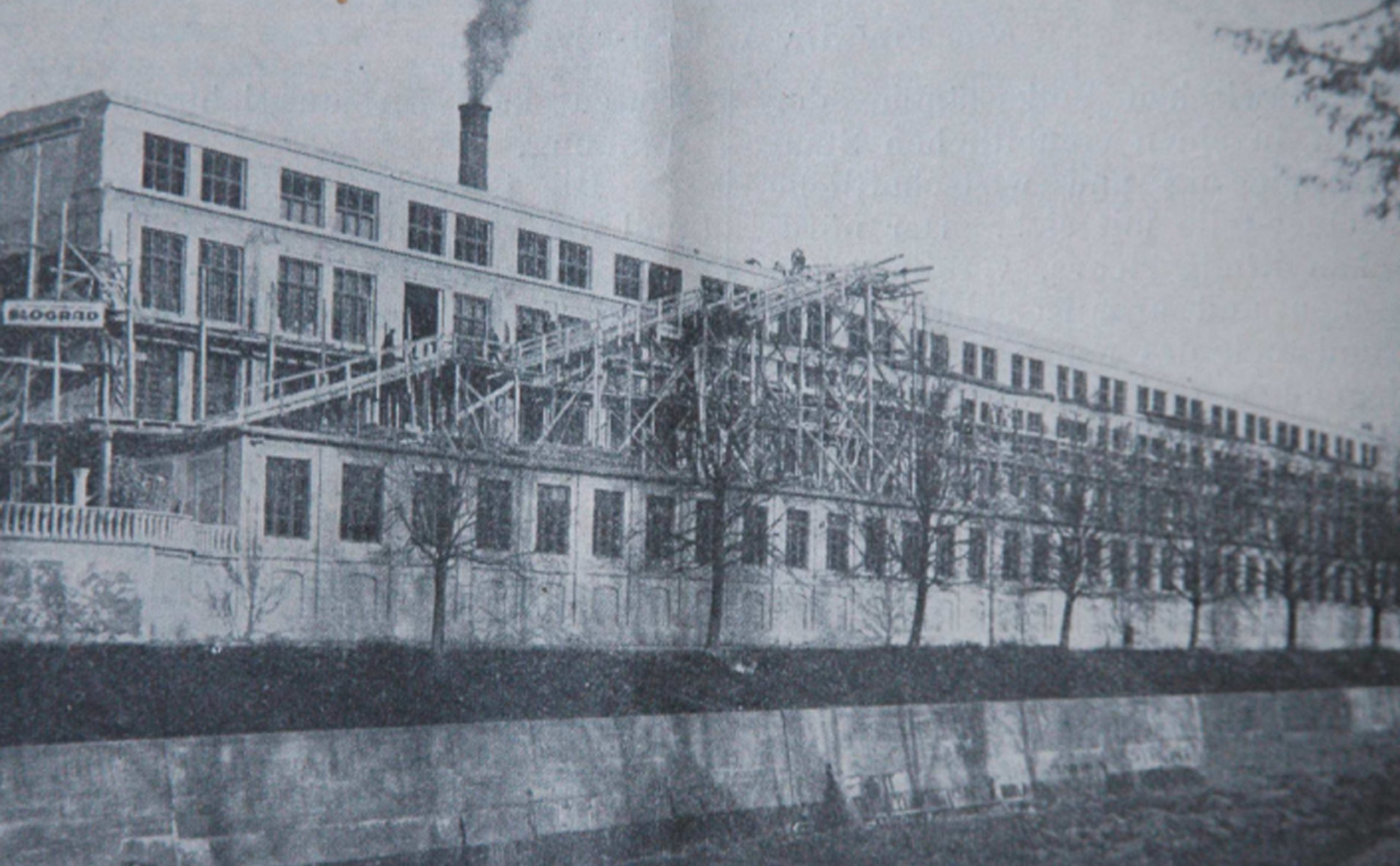

Janez's factory was bought by leather wholesaler Karl Pollak in 1900. He modernised the factory and expanded production to include various leather goods. In 1917, he added a ground-floor hall to the existing factory along the river embankment, and in 1923, he replaced the first floor with a three-storey reinforced concrete superstructure, following the late 19th-century structural system with visible internal primary and secondary beams by the French engineer Francois Hannebique.

Pollak's decision to build the factory in an externally visible reinforced concrete skeleton structure using the Henebique system was still a remarkable feat after World War I. There had never been such an example of a modern skeleton façade in Ljubljana architecture.

Facade

The distinctive vertical articulation of the south façade of the extension, with its outward-swept sharp-edged double columns reflecting the structural design of the building, is a product of contemporary Czech architecture, or so-called Czech Rondocubism. In the post-World War I period in the Czech Republic, it was a kind of offshoot of Art Nouveau in the search for a national style, introducing the characteristic prismatic forms of the circle into architecture. The simple but very effective planning of the vertical and horizontal structural elements achieved a lively yet harmonious design of the unusually long façade.

The author of the construction is the Czech structural engineer Alois Kral, who worked in Ljubljana between the two wars, and archival sources show that he probably also designed the south façade. The building stood out from its suburban surroundings both in size and in its original design. The factory flourished in its early years, but in 1920, at a time of economic crisis, it fell into debt and went bankrupt a few years before the outbreak of the Second World War.

After World War II, the factory passed into state hands. The Ljubljana Council of Industry allocated the factory premises to the Rog Bicycle and Typewriter Factory, which operated on the site until 1992. Soon after production ceased, efforts were made to preserve the factory. The entire factory site was purchased by the Municipality of Ljubljana with the intention of revitalising it and dedicating it to a public urban programme.

The factory area, once on the outskirts of the city, but today in its core, with the peripheral Trubarjeva, Usnjarska and Rozmanova Streets and the Petkovškova Embankment, represents the main urbanistic constants of this area, and with the renovation it introduces into the formerly closed industrial area city-forming activities aimed at various publics.

In the process of planning the redevelopment of the former Rog factory, the integration of the degraded area into the public urban life and the connection of the area with its surroundings, as well as the comprehensive redevelopment of the factory building with the preservation of its cultural and conservation values, were essential starting points. Particular emphasis was placed on the preservation of the structure with the transmission cantilevers still in place as the only remnant of the former industrial process, the large hall spaces with double-sided lighting with typically shaped industrial windows and the pine block wooden flooring typical of industrial buildings, and the preservation of the external appearance of the facades along the Petkovské nabreží (Petkovský Embankment): the 1917 artificial stone and plaster façade of the 1917 extension and the 1923 plastered, unpainted façade of the 1923 extension.

The renovation of the factory building was carried out on the basis of the original urban-architectural solution selected in a public competition in 2008, which envisaged the addition of a transparent communication building along the entire length and height of the courtyard façade. The transparency of the extension, in which the installation core is located, allows the original factory building to be fully perceived in space. Due to the requirements of modern standards, the reinforcement of the historic structure posed both a construction and a conservation challenge. No interventions were allowed on the reinforced concrete skeleton structure on the upper floors, using the Hennebique system, which would have affected the visual appearance of the visible structural elements on both the exterior and the interior of the building. The reinforcement of the historic structure was carried out using carbon strips with minimal intervention on individual structural elements.

The building still expresses its industrial character with typical large coffered windows and unpainted plasterwork of prolonged mortar. During the renovation, the numerous windows were replaced by metal ones, identical in shape, proportions and colour to the original ones. In order to achieve compatibility between the old and the new plaster and the original colour tone of the façade, a naturalistic examination of the original plaster was carried out and, based on the results of the examination, a technological study was drawn up for the rehabilitation mortar used in the renovation. In the multi-purpose hall, a new pine and oiled wood floor was laid in line with the original industrial pine flooring, which could not be preserved due to its contamination with industrial oils and tar.

In the renovated Rog factory, the industrial process will continue with production activities in nine production laboratories on the ground floor, such as textile, wood, metal, green, ceramics, glass and others.

The external appearance of the factory halls in the Rog area is also important in the wider area of the Šempeter suburb and Plečnik's regulated Ljubljanica riverbed, which is a cultural monument of national importance, inscribed on the UNESCO World Heritage List. During the renovation, a great deal of professional attention was paid to preserving the materiality of the exterior, precisely in order to preserve its authentic appearance. Any mechanical damage or graffiti on the facades made of concrete plaster in various surface hand finishes and unpainted extended lime plaster not only has a negative visual impact, but also damages the authentic materials. Their restoration requires professional interventions that are not only costly but also require the intervention of materials that are one of the essential protected components of the built heritage.

Join the live webcast of the CHARTER Alliance Closing Conference: future horizons for vocational skills and training in the heritage sector